Kauko's Massey Ferguson 590 with 300-series auxiliary pump

Kauko and his neighbour Pekka installed a 300-series tandem pump in a 590 and gave these pics to me, thank you! This is almost like my MF565, but oil is sucked trough right side round "dipstick" cover. This tractor had already 3 spool valves to control this timber grapple's jaws and turn. However the tractor had only the lift pump and you must constantly turn the selector (3-way) valve to direct oil either to the 3-point lift or to the grapple's cylinders, because the 3-p lift works only in central position and the grapple only in the EXT2 position. Optionally you could use the 3-p lift with one of the spools, but the lift sinks because of the leaks in the system.

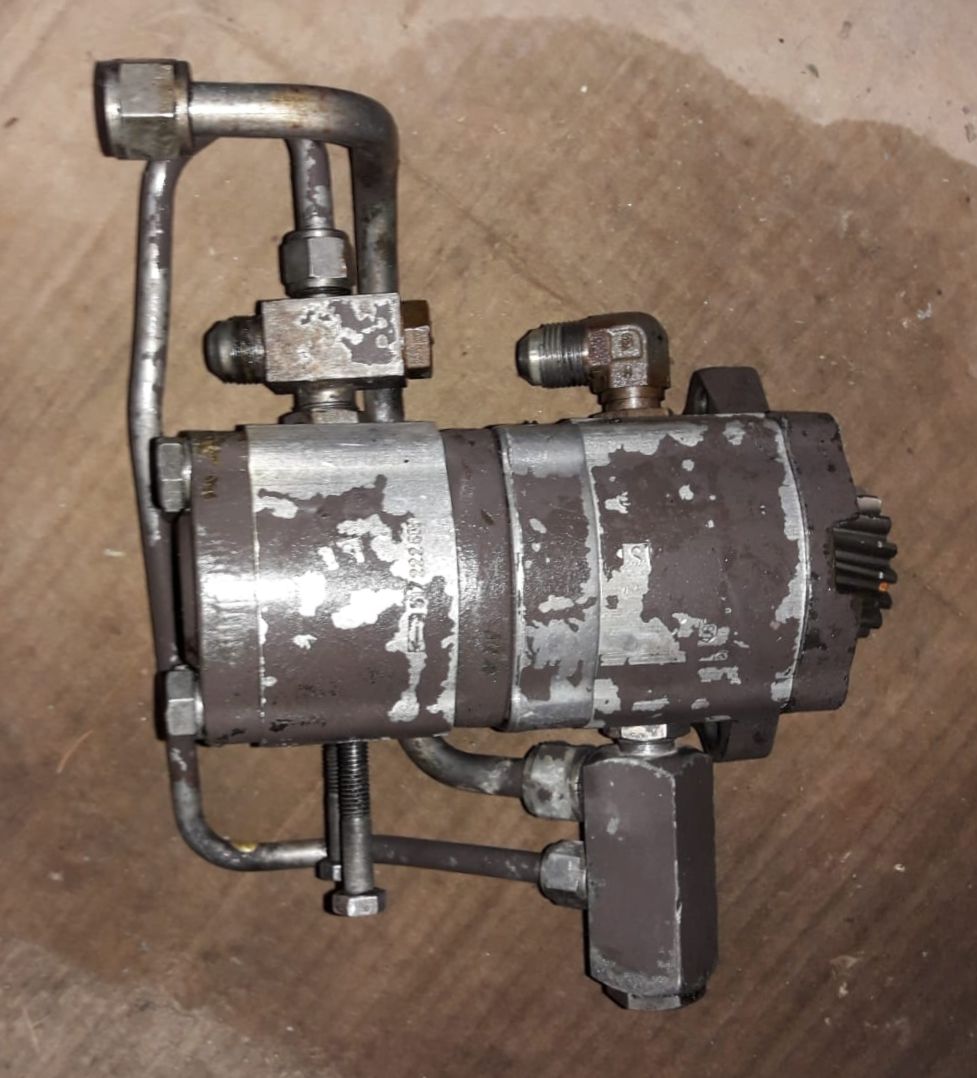

Kauko bought an used 390 pump and it had the 16-teeth drive gear in place. 590 steering pump's 14-teeth gear is unusable with this pump. Kauko got also 390 style suction pipe and filters and other pipe work. Unlike my pump this Bosch-made pump lacks integrated "cold start valve", but same system had been built around the pump using separate parts. The cold start valve short-circuits the flow, so that oil isn't pumped against the orbitrol pressure, which can be 200 bar if the steering cylinder is driven to the utmost length fe.

The spool in this cube shuts off the short-circuit, when the engine is running.

Also these separate valves fit 590 engine side fine. The suction pipe is cut, but is mostly utilized anyway.

The alternator is taken off and the 390 return filter leg installed. Orbitrol's original pressure and return pipes are too small, so new pipes have been fitted.

The return filter in place.

The tandem pump don't have pressure limiting alias relief valve, so a separate adjustable relief valve has been installed for the orbitrol. The 590 has type OSPB orbitrol without integrated relief valve. 390 orbi is type OSPC, which includes relief valve.

Orbi's pressure and return hoses allow the cabin to move.

In my 565 I took the oil trough the bottom hole, used for changing the internal filter. Kauko took the suction trough the right side round "dipstick" cover. For this Pekka lathed a new cover and welded this kind of suction pipe in it, so that he original cover was left for a spare part. The new cover is now missing the draft control lever and also the dipstick. They can be added later, this is the first "temporary" version. Oil level is possible to check by removing one bolt. The bottom one is below the level and the next ones are located around the right level. A window could be even nicer than a stick?

This end is inside the tractor body. This 590 is similar to my 565, they both have Live PTO with dual clutch. IPTO tractors have a hydraulic coupling pack here, that would be very near this pipe. The IPTO tractors probably already have an auxiliary pump inside, so this kind of modification isn't necessary. Also older pre 1975 Masseys have narrower space here, but maybe a flat pipe fits in.

Pipe's outer diameter is 32mm and then there is hose to the suction filter. The suction line must be airtight and obviously this is. The 390 has different central housing with a hole and a curved pipe on the side.

On the right second hand filter housing, for which Pekka welded a cover with a hose connection. 390 spec suction filter fits in.

A 40mm hole was bored in the cab and stairs support for the hose; It's in a safe place.

The pump fits fine on the side of the Perkins. They filled the hose and the pump with oil to give it a good first start. The 390 had some cencors in the return filter housing to alarm, if the filter needs change. I think this filter just blows off, if it gets stuck.

The auxiliary hydraulic's valve board below the cabin floor. The block has a relief valve for the incoming line, that adjusts the system pressure. Keep in mind, that a relief valve is a must somewhere! Now the pressure line comes only from the tandem pump; The lift pump is reserved to the 3-point lift; No combined flow in this case.

The auxiliary hydraulic's return line is led to the selector valve's return port. EXT2 port is blocked with a flattened pipe stump and the selector valve is locked to the central position.

If larger AUX oil flow is required, the EXT2 port can be connected to AUX valve board too. Then both pressure lines need one directional valves to prevent backflow.

Fits perfect and makes a perfect Massey Ferguson 590 model 1977.

Now there is one pump for the 3-point and other for the grapple, so they move simultaneously and independently. If necessary, you can lower and tighten the jaws at the same time for example. You can use the MF pressure control to maintain constant lifting power in 3-point and tow a long log in jaws and the grapple follows and the front wheels stay in the ground. Still you can help the steering by using grapple's turn cylinder. The 590 came to the new modern era, thanks Kauko and Pekka!

Pauli's MF565 auxiliary hydraulics